Non-asbestos gasket sheet

Home » Products » Gasket Sheet » Non-asbestos gasket sheet » Non-asbestos gasket sheet

-

Gasket Sheet

-

Heat Insulation

-

Braided packing

- Asbestos packing with oil and graphite

- Asbestos PTFE Packing

- Pure PTFE Packing

- Pure PTFE Packing with oil

- PTFE Graphite Packing

- PTFE Graphite Packing with oil

- Cotton Fiber Packing with grease

- Cotton Packing with Graphite & oil

- Hempen packing with graphite oil immersed

- Rubberized Asbestos Braided Packing

- Flexible Graphite Packing

- Flax Packing with Grease

- Ramie Fiber Packing

- Kevlar Packing (Aramid Packing)

- Graphite Asbestos packing reinforced with Inconel

- Carbon Fiber Packing

- Carbon Fiber Packing with Graphite

- Ceramic packing with graphite impregnation

- White PTFE Packing with Aramid Corners

- PTFE Packing with Kynol fiber corners

- Graphite packing with PTFE corners

- Graphite packing with PTFE impregnation

- Glass fiber packing with graphite impregnation

- Glass fiber packing with PTFE impregnation

- G-PTFE & Aramid in Zebra Braided Packing

- G-PTFE Packing with Aramid Corners

- Nomex Fiber Packing with rubber core

- Acrylic Fiber Packing

-

Sealing Gaskets

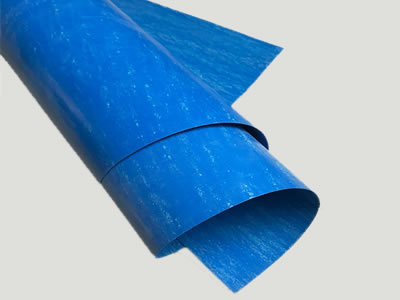

Non-asbestos gasket sheet

Non-asbestos gasket sheet

Non-Asbestos Gasket Sheet are made of the frame materials including aramid fiber and synthetic mineral fiber after speci.....

Non-Asbestos Gasket Sheets are made from a blend of high-performance materials to ensure durability and efficiency. The primary components are aramid fiber, known for its strength and heat resistance, and synthetic mineral fiber, which adds robustness and stability. These fibers are precisely mixed with either natural rubber or oil-resistant rubber, depending on the needed performance. Natural rubber offers flexibility and general sealing, while oil-resistant rubber ensures durability in oily environments. Specialized additives further enhance functionality. The blend is compression molded under high pressure to create uniform, resilient sheets. This process ensures the gasket sheets perform reliably in demanding conditions. Consequently, Non-Asbestos Gasket Sheets are widely used in automotive, chemical processing, and power generation industries for safe and effective sealing solutions.

1) Non-asbestos Gasket sheet series include: NXB200, NXB300, NXB350

The Non-Asbestos Gasket Sheet series, which includes NXB200, NXB300, and NXB350, are designed as alternatives to asbestos Gasket sheets. These sheets are used in equipment involving water, steam, and other substances, serving as sealing materials for pipeline joints. The jointing sheets can withstand working pressures ranging from 1.5 to 8.0 MPa and operate effectively at temperatures between 200 and 350°C. The NXB series ensures reliable performance in demanding environments, offering a safe and efficient sealing solution for various industrial applications.

2) Oil-resistance non-asbestos jointing sheet series include: NNY150, NNY250, NNY300, NNY350

Uses: Substitution of corresponding models of asbestos jointing sheet , Mainly used as the aviation liquid the motive's kerosene, lubricant, the fuel oil and cold air system to join together the seal completely of place the sealing gasket material.

Working pressure : 7.0~12 MPa ,Working temperature : 150 ~350℃

Available Sizes: Thickness: 0.5 to 5mm

1500 x 4500mm, 1500 x 1500mm

The other size is optional or according to the requirements of customers.

At the same time, steel wire net inserted (coated graphite) is available.

Packing: in wooden pallet of about 1000 kgs, 2000kgs net each.

Non-Asbesto jointing Sheet Date Sheet GB/T3985-2008

Item | NXB200 | NXB300 | NXB350 | NNY150 | NNY250 | NNY300 | NNY350 | |

Tensile strength MPa≥ | 6.0 | 8.0 | 11.0 | 8.0 | 10.0 | 12.0 | 15.0 | |

Aging Coefficient ≥ | 0.9 | |||||||

Density g/cm³ | 1.8~1.9 | |||||||

Compressibility % | 12 ± 7 | |||||||

Normal temperature Pliability | Bend 180 degree on the round column (the column diameter is 12 multiple sample thickness), No crack | |||||||

Rebound degree | 35 | 40 | 45 | 40 | 45 | 50 | 50 | |

Worm change Relaxation rate % ≤ | 45 | 45 | 45 | 40 | 40 | 30 | 30 | |

Dipped in IRM903 oil with 149℃ for 5 hours | Horizontal Strain MPa≥ | ---------- | 4.0 | 6.0 | 8.0 | 9.0 | ||

---------- | 30 | |||||||

Appearance change | No air bubble | |||||||

Dipped in ASTM fuel oil B with 21℃-30℃ for 5 hours | Thickness increasing% | ---------- | 0~20 | 5~25 | 5~20 | 5~20 | ||

Pliability | Bend 180 degree on the round column (the column diameter is 12 multiple sample thickness), No crack | |||||||

Cauterization to the metal material | ---------- | No Cauterization | ||||||

Normal temperature oil Airtightness | Medium pressure MPa | ---------- | 7.0 | 9.0 | 11 | 12 | ||

Airtightness request | Keep for 30min, no leak | |||||||

Nitrogen leakage rate [(ml/h.mm)] ≤ | 300 | |||||||